Page 1 of 28 (669 results)

Previous 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Next

Sort:

Relevance

Newest first

Oldest first

Alphabetically

Price increasing

Price decreasing

Product code

Sort:

Relevance

Newest first

Oldest first

Alphabetically

Price increasing

Price decreasing

Product code

Page 1 of 28 (669 results)

Previous 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Next

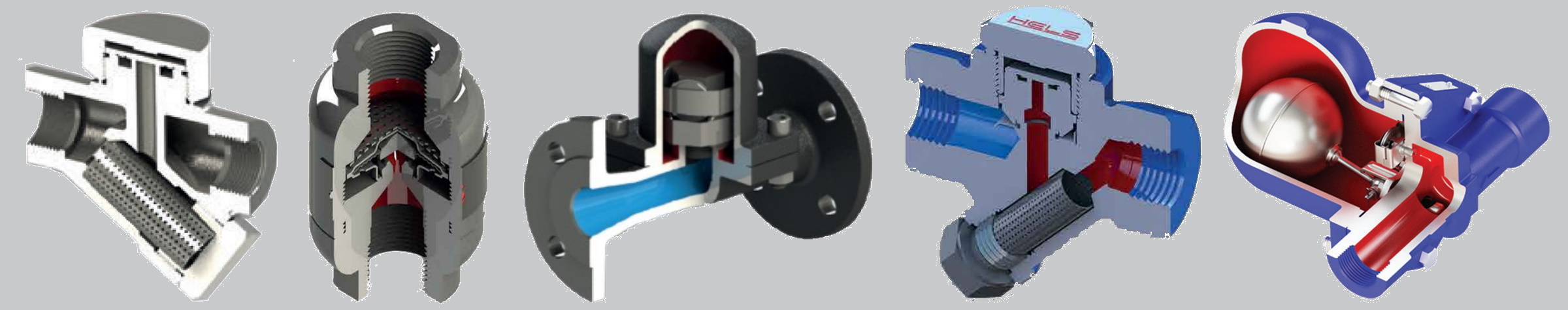

Steam Trap Range at Ebora

We understand that efficient condensate management is crucial for the performance of steam systems. Therefore, we offer various types of steam traps, each with unique features tailored to specific applications.

Types of Steam Traps:

Thermodynamic Steam Traps These steam traps operate on the principle of thermodynamics and are ideal for low-pressure applications. They provide excellent performance and are suitable for both low and high loads.

Float-Operated Steam Traps Efficient in removing condensate under variable loads. The float mechanism regulates condensate discharge, ensuring reliable performance in various conditions.

Thermostatic Steam Traps Suitable for processes with variable loads. These steam traps regulate condensate discharge based on the temperature of the condensate, making them versatile.

Bimetal Steam Trap The bimetal steam trap uses the expansion coefficient of two different metals to control condensate discharge. With temperature changes, the metal strips bend, opening or closing the steam trap.

Inverted Bucket Steam Trap The inverted bucket steam trap opens and closes based on the position of an inverted bucket inside the steam trap. When condensate accumulates, the bucket tilts, opening the steam trap for discharge.

Membrane Steam Trap The membrane steam trap uses a flexible membrane to control condensate discharge. With increasing pressure due to condensate accumulation, the membrane bends, and the steam trap opens.

Venturi Steam Trap The Venturi steam trap utilizes the Venturi effect to discharge condensate. The velocity difference between steam and condensate creates a low-pressure area, allowing the condensate to be discharged.

Function of Steam Traps:

Steam traps play a crucial role in steam and condensate management in various industrial processes. Explore their vital functions:

Condensate removal: Effective removal of condensate to prevent accumulation and harmful effects.

Energy efficiency: Contribute to energy savings by reusing latent heat in condensate.

Equipment protection: Regular condensate removal protects steam equipment from corrosion and erosion.

Stability of pressure and temperature: Maintain the proper pressure and temperature in steam systems for continuous steam supply.

Applications of Steam Traps:

Steam heating systems: Efficient condensate management for significant energy savings.

Steam dryers: Essential for removing condensate in steam dryers, improving drying efficiency.

Process industries: Reliable steam traps for various industries, including chemical, food processing, and textile, where steam is an integral part of the production process.

Steam turbines: Efficient removal of condensate from steam turbines to optimize overall efficiency.

Benefits of a Well-Functioning Steam Trap:

Efficient removal of condensate.

Contribution to energy savings.

Protection of steam equipment from corrosion and erosion.

Maintenance of the proper pressure and temperature in steam systems.

Discover the right steam trap for your specific application and enhance the performance of your steam system with Ebora's high-quality steam traps. Our expert team is ready to advise you. Contact us or place your order directly for reliable and efficient condensate management.

What is steam trap in German?

Steam trap" translates to "Kondensatableiter."