Page 1 of 91 (2179 results)

Previous 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

Next

Sort:

Relevance

Newest first

Oldest first

Alphabetically

Price increasing

Price decreasing

Product code

Sort:

Relevance

Newest first

Oldest first

Alphabetically

Price increasing

Price decreasing

Product code

Page 1 of 91 (2179 results)

Previous 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

Next

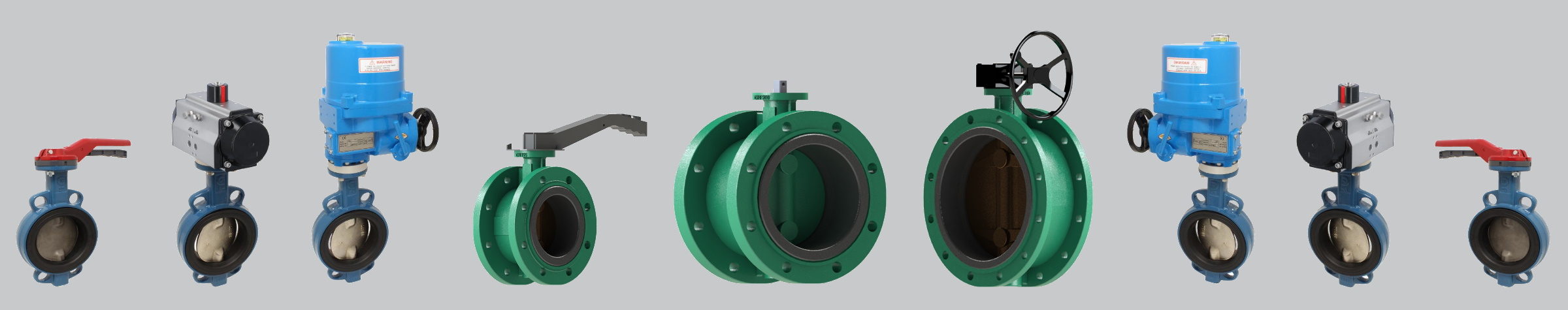

Butterfly valves

The butterfly valve owes its name to the shape of the valve blade, which, with a little good will, can be viewed as a butterfly. Here you will find manually operated, pneumatic and electrically driven butterfly valves. An advantage of a butterfly valve is that it is relatively easy to install in an existing installation by means of flanges.

A Butterfly Valve can be used in installations for liquids, gases, vapours and even powders. Furthermore, a butterfly valve can be used for open/closed purposes and as a simple " control valve ".

Apllication butterfly valve

The butterfly valve is widely used in the following markets:

Maritime sector

Heating and air conditioning

Chemistry and petrochemistry

Drinking water pipes

Appliances and mechanical engineering

Types

In the case of butterfly valves, a distinction is made between different types of valves. Namely the concentric, double eccentric, triple eccentric and even quadruple eccentric. These eccentric valves are also called ‘High Performance’ valves.

Concentric

This is by far the most common type of valve, especially for butterfly valves that are used daily. In this type, the disc is mounted exactly in the middle of the housing. The disadvantage of this is that the disc continues to press against the rubber seal in the event of a prolonged open position. The deformation of the rubber can cause leakage when the valve is closed again. On the other hand, in the event of a prolonged sealing position, the lining continues to press against the disc, requiring a higher breakaway torque to operate the butterfly valve.

Double and triple eccentric

For valves that are not operated on a daily basis, double eccentric valves are the best choice. In this variant, the disc is mounted slightly away from the centre of the body, so that it also rotates away from the centre of the body. As a result, little or no contact is made with the seal, which means that a lower torque is required for operation. In addition, the seal is exposed when open, thus preventing deformation of the rubber. Triple eccentric butterfly valves are mainly available for demanding applications. In this variant, the disc only comes into contact with the seal at the last minute.

As a butterfly valve supplier, Ebora supplies various connection options such as the monoflanged butterfly valve, wafer butterfly valve, lug type butterfly valve and double flanged butterfly valve. For the different components there is a choice of a wide range of materials so that they can be adapted to the requirements of your application for the butterfly valve.

Butterfly valve brands

Besides the butterfly valves on this site we also deliver:

Wouter Witzel butterfly valves

Bray butterfly valves

Ebro butterfly valves

Emerson butterfly valves

Keystone butterfly valves

Tyco butterfly valves

Composeal butterfly valves

Affco butterfly valves

etc.

Materials Stainless steel Butterfly valves, cast iron butterfly valves, bronze butterfly valves

All mentioned butterfly valves can be supplied by Ebora as:

Electrically operated butterfly valve

Pneumatically operated butterfly valve

Butterfly valve worm gear operated

Butterfly valve manually operated