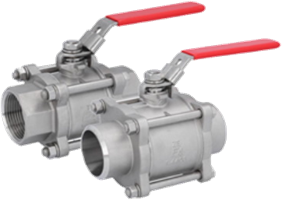

Ball valve

A ball valve is a form of a quarter turn valve that uses a hollow, perforated and rotatable ball valve to regulate the flow. It is open when the ball hole is in line with the flow and closed when it is rotated 90 degrees by the valve handle. The handle is flat in line with the flow when it is open and is perpendicular to the flow when it is closed, allowing easy visual confirmation of the valve's status.

Advantages of ball valves

The ball valve is durable, performs well after many cycles, is reliable, and closes securely even after long periods in the same position. These qualities make them an excellent choice for shut-off and control applications, where they are often preferred to globe valves, but they lack fine control in throttle applications.

The ease of operation, repair and versatility of the ball valve lend it to extensive industrial use, with pressures up to 1000 bar and temperatures up to 400°C, depending on the design and materials used. Dimensions usually vary from DN15 to DN200. The ball valve housings are made of metal, plastic or metal with a ceramic; floating balls are often chrome plated for durability.

A disadvantage of a ball valve is that it collects water in the middle cavity when it is closed. In the event of frost, the sides of the valve may crack due to the expansion of the ice formation. An option for cold climates is the "freeze tolerant ball valve". This type of valve is equipped with a frost plug on the side, so that in case of frost, the frost plug breaks (acts as a rupture disk), making a simple repair possible. Instead of replacing the entire valve, all you have to do is screw in a new freezer plug.

Ball valves are available in:

- Brass

- Stainless steel

- Cast iron

- Ductile iron

- Carbon steel

- Plastic type:

- ABS (Acrylonitrile-butadiene-styrene)

- PVC-U (Polyvinyl Chloride), also known as PVCu or uPVC.

- PVC-C (polyvinyl chloride, chlorinated), also known as PVCc or cPVC.

- PP (Polypropylene)

- PE (polyethylene), also known as LDPE, MDPE and HDPE

- PVDF (polyvinylidene fluoride)

- PTFE

- PFA

There are three types of ball valves:

A full flow or better known as a full bore ball valve has an oversized ball so that the hole in the ball is the same size as the pipeline, resulting in a lower friction loss. The flow is unlimited, but the valve is larger and more expensive, so this is only used where free flow is required, for example in pipelines where pigging is necessary.

In Reduced port (better known as reduced bore ball valves), the flow through the valve is one pipe size smaller than the pipe size of the valve, resulting in a flow area smaller than the pipe size of the valve.

A V-port ball valve has either a "v" shaped bullet or a "v" shaped seat. This enables linear and even flow characteristics. When the valve is in the closed position and the opening is started, the small end of the 'v' is opened first, allowing a stable flow control during this phase. This type of design requires a generally more robust construction due to higher fluid velocities, which can damage a standard valve. These can be referred to as a type of control valve, but are usually not as accurate as a control valve, needle valve or pressure control valve.