Gate Valve

In accordance with the Machinery Directive 2006/42/EC, all automated Gate Valves supplied by Ebora come with protective covers. If your knife edge Gate Valve is used in inaccessible spaces, we can, upon special request, supply them without these protective plates.

Gate Valve designed for installation between flanges according to EN 1092-1 Type 11 Form B - PN10. ANSI 150 flanges available on request.

Due to their design, Gate Valves are often referred to as slide valves, knife edge valves, knife edge Gate Valves, slide gates, rotary valves, or spade valves. These Gate Valves are similar to these slide valves and can be used for similar applications.

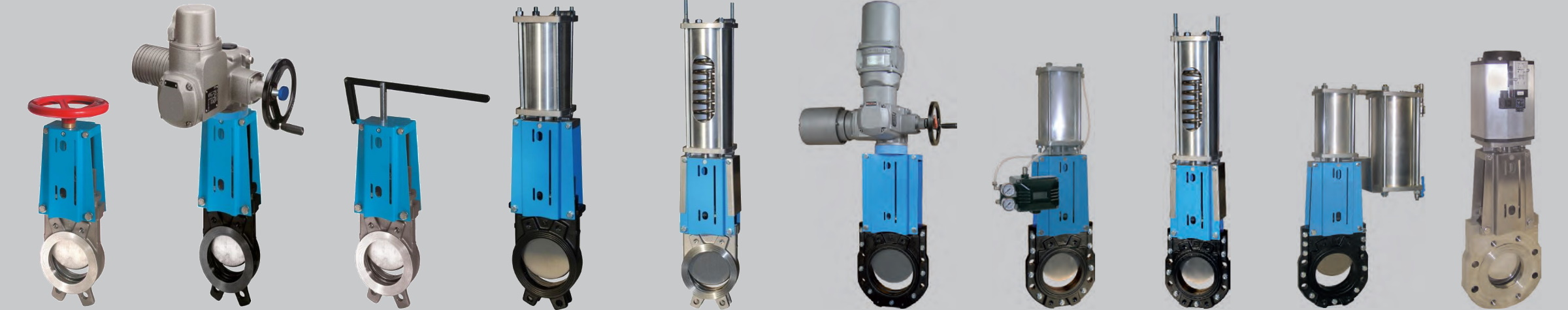

The operation of the Gate Valve can be:

Our EBWGE and EBWEB knife edge Gate Valves are constructed in such a way that they can both be equipped with the same control elements. This design allows the customer to change the operation themselves.

For Which Media Are Gate Valves Commonly Used?

Gate Valves can be used for various media, but it is always advisable to seek advice regarding usage or any additional options that may extend their lifespan. Not suitable for steam.

- Liquids and contaminated media containing fibers

- Viscous media

- Slurry, pulp, and manure

- Dredged sludge, sewage sludge, and tar sand

- Sewage, polluted water, and wastewater

- Biomass

- Viscous media

- Paper (pulp)

- Bulk and bulk goods, such as powders and granulates

- Sand, gravel, gypsum, and cement

- Potato peels, eggshells, and slaughter waste

Features of Our Gate Valves

Housing of Knife Edge Gate Valve

GG-25, grounded and polyester-coated (190 °, baked for 20 minutes) or stainless steel 1.4408. Total length according to EN 558-1 series 20.

Gate Valve Seat Seals

Depending on the version, metal sealing or soft sealing with NBR, EPDM, FKM, silicone, or PTFE sealing

Metal Sealing

Metal sealing is suitable for many applications where minor leakage poses no issues. Estimated leakage: 0.5%-1.5% of the Kv value for liquid and low-viscosity media. Also applicable at higher medium temperatures. We recommend contacting us to discuss the application.

NBR

This is a resilient seal used in liquids that may contain fats or oils at temperatures of -25 °C and 90 °C. (suitable for non-frozen media)

EPDM

This is a resilient seal widely used in various applications for aqueous media with temperatures ranging from -35 °C to 120 °C. It can also be used with abrasive substances. (suitable for non-frozen media)

FPM

Suitable for corrosive applications and continuous high temperatures. We recommend contacting us to discuss the application.

SILICONE

Mainly used in the food industry and for pharmaceutical products with temperatures not exceeding 200 °C. We recommend contacting us to discuss the application.

PTFE

Suitable for corrosive applications and pH between 2 and 12. Estimated leakage: 0.5% of the Kv value for liquid and low-viscosity media.

Gland packing for knife-edge Gate Valves

3-piece packing set, standard:

1x synthetic fiber, PTFE-coated, PTFE / oil filling

1x edge-reinforced (Kevlar®) packing

1x NBR, EPDM, or FKM ring (bulk material on request)

Other types of packing are available, for example:

- X-ring

- Edge-reinforced seal

- Copper gasket

- Stainless steel seal

Sliding plate (blade)

Material: stainless steel 1.4307 or 1.4404

Other plate versions are available, for example:

- hardened

- polished

- MPF-coated: anti-adhesive and highly resistant to acids and chemicals

Spindle

Double bearing shaft. The sliding blade (thus the place slide) is only executed against or on the seal at the end of the closing process, so no grinding during the adjustment process and thus a lower torque. The valve blade acts like a knife and can partially cut media, from which the terms knife slide or spade slide are derived.

Material: stainless steel 1.4305 or 1.4404.

Leak rate

Please note that a leak rate of 0.4% of the Kv value can be expected for metal closing Gate Valves (media with low viscosity).

Gate Valve versions

- Single-sealing Gate Valves

This version is often used for wastewater, powders, manure, and slaughter waste

- Double-sealing knife-edge Gate Valve

The double-sided seal is chosen in closed systems where the pressure can come from both sides. They are independent of the pressure direction. Suitable for wastewater, contaminated water

- Gate Valves with a deflector to guide the flow to the center of the passage in abrasive media to prevent wear as much as possible. To be applied in, among others, cement, sand, gravel, plaster, brine, abrasive media, granulates, and bulk transport.

- Gate Valves with continuous plate, double-sealing.

These knife-edge Gate Valves are used in systems where one wants to minimize dead spaces in the open position (for example, the paper industry) and thus better protect the seals.

Common (Special) Knife-Edge Gate Valve Options:

- External pressure vessel to create a fail-safe function (closing or opening) in case of compressed air failure.

- Limit switches for the open/close positions of the knife-edge Gate Valve. Both as a mechanical switch and inductive proximity switch.

- Kife-edge Gate Valves entirely made of stainless steel (including the structure)

- Electropneumatic valve positioner

- V-notch for control applications

- Deflector for abrasive media

- Spindle extension

- Mechanical stops

- Locks

- Manual emergency operation

- Solenoid valve

- Flushing device allowing the valve seat to be cleaned through holes in the body.

Pneumatically Operated Knife-Edge Gate Valve with Fail-Safe Function

When pumping liquids and powdery media with fiber components, viscous media, wastewater, sewage sludge, or food, knife-edge Gate Valves are the preferred choice for closing media flows. By using single-acting pneumatic actuators with spring return, this also applies to safety applications with a safe state OPEN or CLOSED.

The knife-edge Gate Valves with fail-safe function are equipped with single-acting, pneumatically actuators with spring return. Coordinated spring packages in the actuators ensure that the knife-edge Gate Valve reliably reaches their end positions even with viscous or pasty media. Depending on the application, you can choose between spring-closed (fail-safe closed) or spring-open (fail-safe open) options.

Due to direct mounting, the Gate Valve and pneumatic actuator form a compact and functional unit. After mounting the knife-edge Gate Valve in the pipelines and connecting the control lines, the slide valves are ready for use. Side protection plates provide the necessary protection against unintended contact, making it easy to comply with the requirements of the Machinery Directive 2006/42/EC.

Depending on the operating conditions, you can choose between a single-sided knife-edge Gate Valve with a one-piece monoblock housing or a double-sided knife-edge Gate Valve with a two-piece screw housing. The housings are made of gray cast iron GG-25, and their high-quality polyester coating is permanently baked in 20 minutes at a temperature of 190 °C. Alternatively, the knife-edge Gate Valves are also available in stainless steel 1.4408.

The valve blades, made of stainless steel 1.4301 or 1.4401, reliably seal against the seat seals of NBR. The single-sealing slide can also be equipped with seals of EPDM, FKM, PTFE, or with a metal seal, making a suitable sealing material available for almost all applications and flow media.

The flange dimensions of the knife-edge Gate Valve EBWG, which are standardly available from DN50 to DN400, are dimensioned for flanges according to PN10 EN1092-1. However, for larger nominal sizes or flanges according to PN16, ANSI150, or special flanges, corresponding knife-edge Gate Valves are also available in the program. The installation lengths correspond to the specifications of the EN558-1 series 20 standard.

In addition to the operating variant described here, the Gate Valves are also available with a handwheel, hand lever, chain wheel, electric actuator, hydraulic actuator, or pneumatically double-acting. For safety applications, the pneumatic actuator can also be equipped with a compressed air tank, allowing a controlled approach to a safety position if the compressed air supply fails (Failsafe closed, failsafe open).

Knife-Edge Gate Valve for Control or Dosing with Digital Valve Positioner

For this application, we can provide the knife-edge Gate Valve with a V-shaped passage to more precisely control the flow. Of course, we can equip the automated Gate Valves, electrically or pneumatically, with a positioner for the correct position of the plate. The positioner is adjusted and tested upon delivery, ready for use.

Where are knife-edge Gate Valves commonly used?

- Pulp industry

- Mining

- Silo emptying

- Paper industry

- Biogas production

- Wastewater treatment

- Sewage treatment

- Slaughterhouses

- Under silos

- Drainage systems

Tip:

A defective knife-edge Gate Valve is not difficult to repair but even easier to prevent. These problems are usually caused by mineral buildup, so you should fully close and open your knife-edge Gate Valves every few months to solve potential issues.